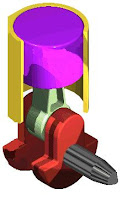

IC ENGINE :

In case of gas power cycle, gas is used as the working fluid. It does not undergoes any phase change rather the heat comes from burning the fuel. The combustion of fuel may take place inside or outside the engine. These engines are non-cyclic heat engines.

OTTO CYCLE

One very common type of IC engines used in automobiles is the spark ignition (SI) engine.

P-V diagram of Otto cycle

Intake (step 5-1):

The inlet valve is open. The piston moves outwards admitting fuel air mixture into the cylinder at constant pressure.

Compression (step 1-2):

Both the valves close and the piston compresses

the combustible mixture to the minimum volume.

This minimum volume is also known as clearance volume.

Combustion (step 2-3):

The air-fuel is ignited by a spark plug, combustion takes place and there is an increase in temperature and pressure.

Expansion (step 3-4):

The products of combustion do work on the piston, which moves out and the pressure and

temperature of the gas decrease.

Blow down (step 4-1):

The exhaust valve opens and the pressure drops to the initial position.

Exhaust (step 1-5):

When the exhaust valve opens the piston moves in to expel the combustion products from the cylinder at constant pressure. The series of processes described above constitute a mechanical cycle and not a thermodynamic cycle. The process is completed in four strokes of the piston.The efficiency of the Otto cycle depends only on the compression ratio, higher the compression ratio, the higher will be the efficiency.

DIESEL CYCLE

By compressing air alone in place of fuel-air mixture and then injecting the fuel into the cylinder in the spray form when combustion is desired then the limitation of compression ratio in all SI engine can be overcome.

P-V diagram of Diesel Cycle

Intake (step 1-2):

The inlet valve is open. The piston moves outwards admitting fuel air mixture into the cylinder at constant pressure.

Fuel injection and combustion (step 3-4):

The fuel valve is open, the fuel is sprayed at high pressure into the hot compressed air and combustion takes place at constant pressure.

Expansion (step 4-5):

The products of combustion do work on the piston, which moves out and the pressure and

temperature of the gas decrease.

Blow down (step 5-6):

The exhaust valve opens and the pressure drops to the initial position.

Exhaust (step 6-1):

When the exhaust valve opens the piston moves in to expel the combustion products from

the cylinder at constant pressure.

The above processes constitute an engine cycle which is completed in four strokes of the piston or two revolutions of the crankshaft.

No comments:

Post a Comment